Enable Zaxis Servo Functionality For GRBL MI Inkscape Extension Electric DIY Lab Diy

GRBL is an open source software or firmware which enables motion control for CNC machines. We can easily install the GRBL firmware to an Arduino and so we instantly get a low cost, high performance CNC controller. The GRBL uses G-code as input, and outputs motion control via the Arduino .

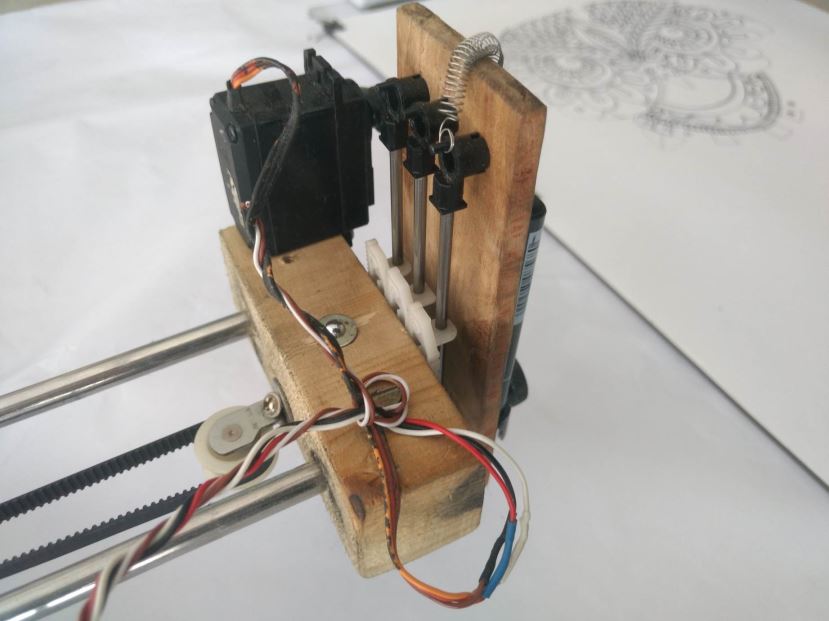

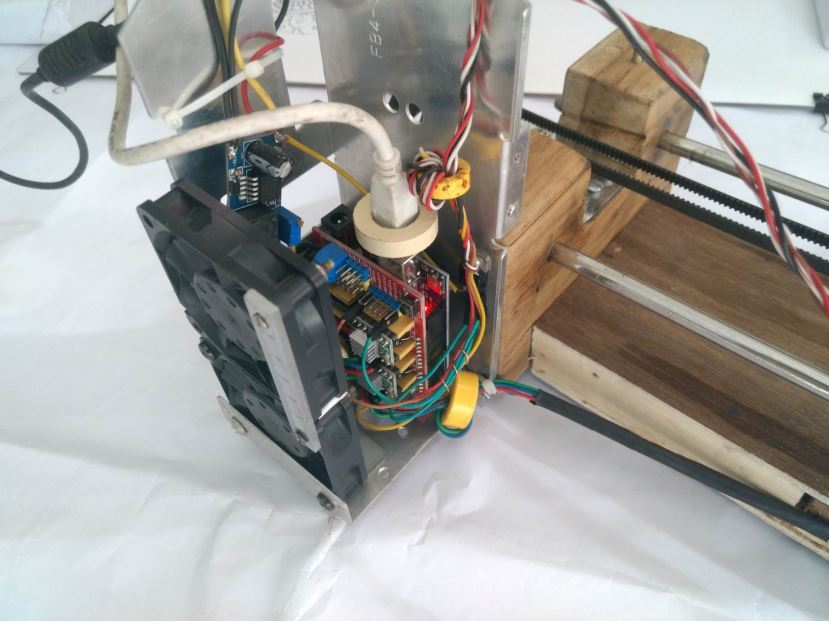

Crazy Engineer’s Drawing Robot / Arduino GRBL CoreXY Servo Drawbot

Add a Servo to a CNC machine running grbl software and control it with G-code commands.

GRBL CNC Shield + Z Axis servo MIGRBL Electric Diy Lab

Try this test sketch with the Servo library to see how your servo responds to different settings, type a position (0 to 180) or if you type a number greater than 200 it will be interpreted as microseconds, in the top of serial monitor and hit [ENTER], start at 90 (or 1500) and work your way toward zero 5 degrees (or 50 micros) at a time, then to.

AxiDraw CNC Arduino GRBL CoreXY Servo Drawbot Writing Robot

• 3 yr. ago I got the servo doing *something* using a modified version of GRBL from here: https://github.com/bdring/Grbl_Pen_Servo. I'm using a continuous rotation servo, so when I fired it up it spins constantly. I expected this would be because of the values being sent being for a regular servo.

Using Grbl’s Spindle PWM to Control a Servo at Blog

January 1, 2022 [Frank Herrmann] had an interesting idea to turn a geared DC motor into a servo motor assembly, but with a stepper motor-like interface.

How to Control a Servo Using GRBL Arduino Cnc, Cnc Router, Alcohol Dispenser, E Motor, Pen Down

Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328.

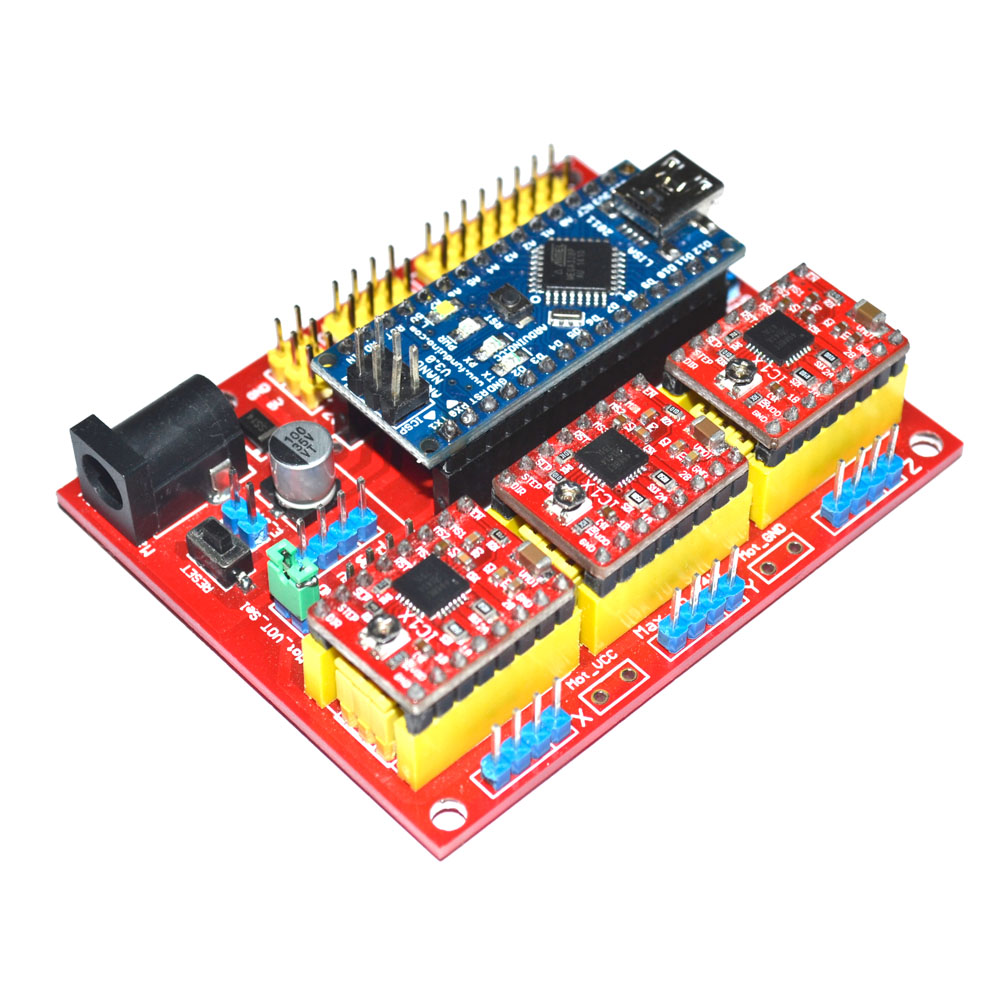

Grbl pinout arduino nano

By the way, I'm using NEMA 17 for my X and Y axis and servo SG90 for my Z axis. X and Y axis can move well, but for the Z it can't move at all. I'm trying to follow the step like modify the spindle-control.c or config.h even from another source but it's same, it can't move at all.

How to change the GRBL algorithm from PWM to servo controlled for plotter? YouTube

GRLB is the open source firmware freely available for every one, GRBL is used as firmware for CNC machine. GRBL CNC Shield is used as controller for CNC machine, GRBL shield and GRBL firmware is very best for 3 axis stepper CNC machine.

grbl on uCNC_controller dev update new mode available emulated Zaxis servo control YouTube

The adapted grbl firmware can be found in the GRBL plotter setup (grbl_v1.1f_Servo_switch_dir_step.hex). Using old pc Windows XP: the regular setup (file 'GRBL-Plotter_Setup.exe') doesnt work (setup is made with Inno-Setup, which supports down to Windows Vista), instead use the extracted folder from 'GRBL-Plotter_1xxx_release.zip' and start.

How to Control a Servo Using GRBL 8 Steps (with Pictures) Instructables

GRBL, a name derived from "garble", is an open-source, high-performance software for controlling the motion of machines that move, like 3D printers, laser cutters, and of course, CNC machines. It interprets G-code, a programming language for CNC operations, and transforms it into electrical signals to control stepper motors or servo motors.

Servo Axis Feature · bdring/Grbl_Esp32 Wiki · GitHub

Subscribe 24K views 8 years ago grbl 0.9i with Servo motor support Use the PIN D11 to drive the servo. Use the commands M03 Sxxx --xxx between 0 and 255.more.more grbl 0.9i with.

Dynamixel Servos in Grbl_ESP32 at Blog

To be consistent with your GRBL controller, you should set these to the same values you have for min/max spindle speed in GRBL's $31 and $30 settings, but this is not absolutely necessary. Whatever S### value provided is re-scaled from the minimum/maximum speed range to the servo_min_duty_cycle and servo_max_duty_cycle range when using rpi.

Servo rotates randomly · Issue 1 · bdring/Grbl_Pen_Servo · GitHub

This instructable explains how to: free up a PWM servo pin by modifying GRBLversion 1.1f, configure GRBL for coreXY plotters, create a g-code calibration file using Inkscape 0.92, insert the necessary pen-lift control codes using "GcodePostProcessor" [2], configure your plotter settings and. send the modified g-code to your plotter.

GRBL CNC Shield + Z Axis servo MIGRBL Electric Diy Lab

GitHub - vankesteren/grbl-servo: Slighty edited pen plotter version of grbl, an open source, embedded, high performance g-code-parser and CNC milling controller written in optimized C that will run on a straight Arduino vankesteren / grbl-servo Public forked from gnea/grbl 1 branch 8 tags This branch is 5 commits ahead of gnea:master . #2

China AC Servo step/dir with Grbl YouTube

Grbl with Pen Servo Feature (Arduino UNO - ATMega328p version) This is standard Grbl modified for use with a pen plotter that has a hobby servo for the pen up / down. The servo will have two positions representing up and down.

Crazy Engineer’s Drawing Robot / Arduino GRBL CoreXY Servo Drawbot

GitHub - cprezzi/grbl-servo: Special Grbl version for use with servo instead of spindle or laser. Terms Privacy Docs Contact GitHub Support Manage cookies cprezzi / grbl-servo Public forked from gnea/grbl eggbot 2 branches 0 tags This branch is 7 commits ahead, 19 commits behind gnea:master